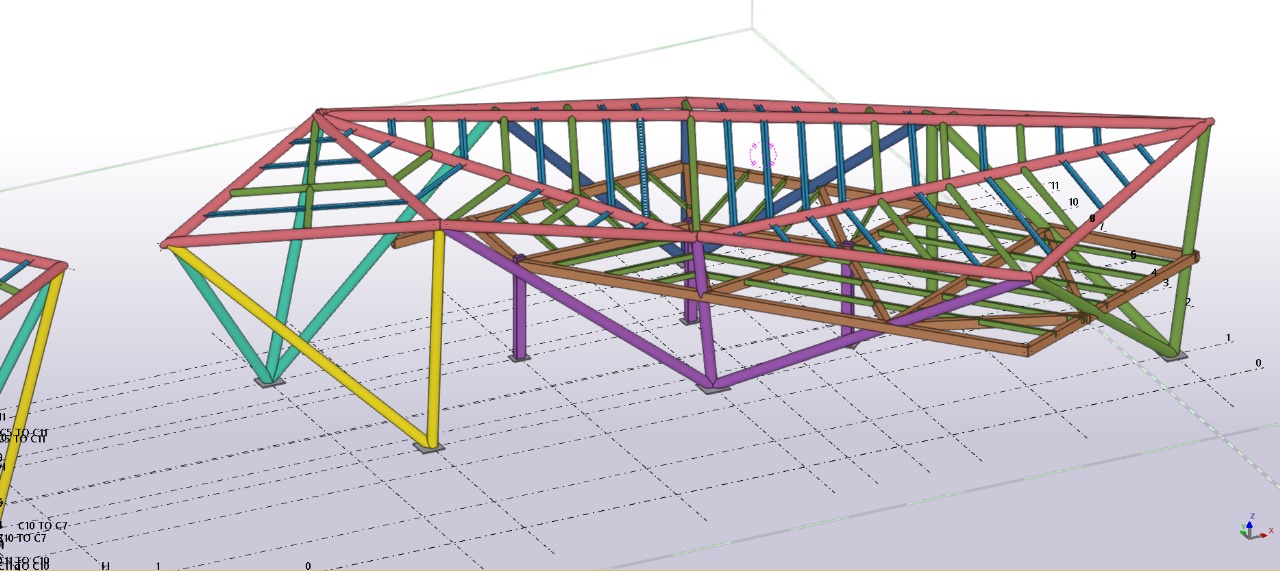

Overcoming Fabrication Challenges in a Tubular Steel Structure: A Small Case Study of the MEPZ Canteen Building, Chennai

In the heart of Chennai, our team took on an ambitious project to build a tubular steel structure for a canteen facility at the MEPZ (Ministry of Commerce and Industries) unit. What made this project truly special was its distinctive architectural design, aimed at giving the facility a fresh, modern look. But with all that innovation came its fair share of challenges, especially during the fabrication and erection stages of the structure.

Project Overview: A Modern Tubular Steel Structure

The project involved constructing a canteen facility building with an unconventional shape that showcased modern architectural elegance. The tubular steel design was chosen for its versatility, strength, and ability to complement cutting-edge architectural styles. However, as we progressed, we encountered several obstacles during the fabrication and erection phases.

The Challenge: Precision and Space Constraints in Tubular Structures

Tubular steel structures are awesome for modern architecture because of their looks and strength. But when it comes to creating unique shapes, getting the cutting and joining of the tubular members just right is crucial.

During the fabrication phase we encountered the following challenges:

Mismatched Sizes: Manual cutting of tubular steel members resulted to inconsistent dimensions. This led to mismatched connections that didn’t align with the design specs.

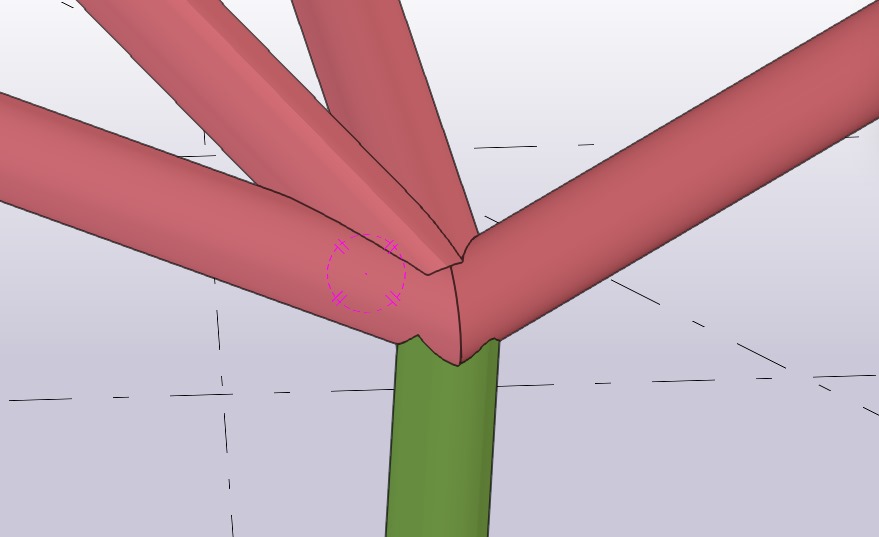

Limited Space for Joints: Due to the complex geometry of the structure, there was not enough space to join multiple tubes to a single member. Manual methods made it worse, resulting to uneven joints.

Manual Errors: Relying on manual cutting and fabrication introduced errors, resulting to imprecise joints. These deviations affected the structural integrity and aesthetics of the building.

The Solution: Tubular Laser Cutting

To overcome these challenges we used tubular laser cutting. This technology was a game changer, addressing our problems at the root:

Precision Cutting: Tubular laser cutting provided precise cuts, every member met the exact dimensions required by the design. No more mismatches and uneven joints.

Limited Space for Joints: The precision of laser cutting allowed us to maximize the available space for connections, joining multiple tubes to a single member.

Labor and Time Savings: By automating the cutting process we minimized manual intervention, reduced labor costs and time.

Structural Integrity: The precision and consistency achieved through laser cutting resulted to joints that met the highest standards, ensuring the safety and durability of the structure.

Key Takeaways

We learned a lot about the importance of using advanced fabrication methods for modern architecture. Tubular laser cutting solved our immediate problem and reinforced the importance of precision and efficiency in design and execution.

Why Tubular Laser Cutting for Modern Architecture?

Tubular laser cutting is a game changer in modern architectural construction. It’s precise, minimizes errors and reduces project timeline and cost. For any project with complex geometry or tubular steel structure, we highly recommend this.

How to Build a Tubular Steel Structure the Right Way

If you’re building a tubular steel structure, here are the steps to follow:

Use Advanced Cutting Technology:Use tubular laser cutting to get precision and minimize errors.

Work with Experienced Fabricators: Collaborate with people who understand tubular steel structures and can provide innovative solutions.

Plan for Complex Joints: Design the joints carefully especially when multiple tubes meet. Advanced software and tools can help you simulate the best fit.

Quality Control: Inspect regularly during fabrication and erection to ensure the structure meets design and safety standards.

Optimize Labor and Resources: Advanced methods like laser cutting reduces manual labor, saves cost and fast tracks the construction process.

Conclusion: The Future of Tubular Steel Structures

The successful completion of the MEPZ canteen facility in Chennai showcases how innovative technology, like tubular laser cutting, can truly transform the way we approach modern architectural construction. It’s not merely about addressing current challenges; it’s about raising the bar for quality, efficiency, and design creativity.

If you’re looking to build a tubular steel structure the right way or want to incorporate cutting-edge architectural designs with precision, don’t hesitate to get in touch with us. We’re here to support you at every stage of your construction journey.